|

| August 23, 2016 | Volume 12 Issue 32 |

Electrical/Electronic News & Products

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Conductive Brush Ring overcomes current leakage in EV powertrains

SKF's new Conductive Brush Ring paves the way to greater reliability and longer life in high-performance electric vehicle powertrain systems. Using pure carbon fiber bristles, it provides a reliable electrical connection between an EV eAxle rotor shaft and its housing. When used in combination with SKF Hybrid ceramic ball bearings, it helps to alleviate parasitic current effects that can lead to premature failure in bearings and other components. Available in different configurations for wet (oil-lubricated) motor designs -- and soon for dry (sealed) applications.

SKF's new Conductive Brush Ring paves the way to greater reliability and longer life in high-performance electric vehicle powertrain systems. Using pure carbon fiber bristles, it provides a reliable electrical connection between an EV eAxle rotor shaft and its housing. When used in combination with SKF Hybrid ceramic ball bearings, it helps to alleviate parasitic current effects that can lead to premature failure in bearings and other components. Available in different configurations for wet (oil-lubricated) motor designs -- and soon for dry (sealed) applications.

Learn more.

Intro to reed switches, magnets, magnetic fields

This brief introductory video on the DigiKey site offers tips for engineers designing with reed switches. Dr. Stephen Day, Ph.D. from Coto Technology gives a solid overview on reed switches -- complete with real-world application examples -- and a detailed explanation of how they react to magnetic fields.

This brief introductory video on the DigiKey site offers tips for engineers designing with reed switches. Dr. Stephen Day, Ph.D. from Coto Technology gives a solid overview on reed switches -- complete with real-world application examples -- and a detailed explanation of how they react to magnetic fields.

View the video.

Bi-color LEDs to light up your designs

Created with engineers and OEMs in mind, SpectraBright Series SMD RGB and Bi-Color LEDs from Visual Communi-cations Company (VCC) deliver efficiency, design flexibility, and control for devices in a range of industries, including mil-aero, automated guided vehicles, EV charging stations, industrial, telecom, IoT/smart home, and medical. These 50,000-hr bi-color and RGB options save money and space on the HMI, communicating two or three operating modes in a single component.

Created with engineers and OEMs in mind, SpectraBright Series SMD RGB and Bi-Color LEDs from Visual Communi-cations Company (VCC) deliver efficiency, design flexibility, and control for devices in a range of industries, including mil-aero, automated guided vehicles, EV charging stations, industrial, telecom, IoT/smart home, and medical. These 50,000-hr bi-color and RGB options save money and space on the HMI, communicating two or three operating modes in a single component.

Learn more.

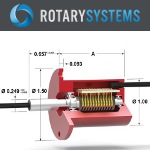

All about slip rings: How they work and their uses

Rotary Systems has put together a really nice basic primer on slip rings -- electrical collectors that carry a current from a stationary wire into a rotating device. Common uses are for power, proximity switches, strain gauges, video, and Ethernet signal transmission. This introduction also covers how to specify, assembly types, and interface requirements. Rotary Systems also manufactures rotary unions for fluid applications.

Rotary Systems has put together a really nice basic primer on slip rings -- electrical collectors that carry a current from a stationary wire into a rotating device. Common uses are for power, proximity switches, strain gauges, video, and Ethernet signal transmission. This introduction also covers how to specify, assembly types, and interface requirements. Rotary Systems also manufactures rotary unions for fluid applications.

Read the overview.

Seifert thermoelectric coolers from AutomationDirect

Automation-Direct has added new high-quality and efficient stainless steel Seifert 340 BTU/H thermoelectric coolers with 120-V and 230-V power options. Thermoelectric coolers from Seifert use the Peltier Effect to create a temperature difference between the internal and ambient heat sinks, making internal air cooler while dissipating heat into the external environment. Fans assist the convective heat transfer from the heat sinks, which are optimized for maximum flow.

Automation-Direct has added new high-quality and efficient stainless steel Seifert 340 BTU/H thermoelectric coolers with 120-V and 230-V power options. Thermoelectric coolers from Seifert use the Peltier Effect to create a temperature difference between the internal and ambient heat sinks, making internal air cooler while dissipating heat into the external environment. Fans assist the convective heat transfer from the heat sinks, which are optimized for maximum flow.

Learn more.

EMI shielding honeycomb air vent panel design

Learn from the engineering experts at Parker how honeycomb air vent panels are used to help cool electronics with airflow while maintaining electromagnetic interference (EMI) shielding. Topics include: design features, cell size and thickness, platings and coatings, and a stacked design called OMNI CELL construction. These vents can be incorporated into enclosures where EMI radiation and susceptibility is a concern or where heat dissipation is necessary. Lots of good info.

Learn from the engineering experts at Parker how honeycomb air vent panels are used to help cool electronics with airflow while maintaining electromagnetic interference (EMI) shielding. Topics include: design features, cell size and thickness, platings and coatings, and a stacked design called OMNI CELL construction. These vents can be incorporated into enclosures where EMI radiation and susceptibility is a concern or where heat dissipation is necessary. Lots of good info.

Read the Parker blog.

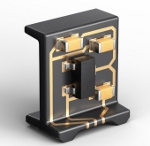

What is 3D-MID? Molded parts with integrated electronics from HARTING

3D-MID (three-dimensional mechatronic integrated devices) technology combines electronic and mechanical functionalities into a single, 3D component. It replaces the traditional printed circuit board and opens up many new opportunities. It takes injection-molded parts and uses laser-direct structuring to etch areas of conductor structures, which are filled with a copper plating process to create very precise electronic circuits. HARTING, the technology's developer, says it's "Like a PCB, but 3D." Tons of possibilities.

3D-MID (three-dimensional mechatronic integrated devices) technology combines electronic and mechanical functionalities into a single, 3D component. It replaces the traditional printed circuit board and opens up many new opportunities. It takes injection-molded parts and uses laser-direct structuring to etch areas of conductor structures, which are filled with a copper plating process to create very precise electronic circuits. HARTING, the technology's developer, says it's "Like a PCB, but 3D." Tons of possibilities.

View the video.

Loss-free conversion of 3D/CAD data

CT CoreTech-nologie has further developed its state-of-the-art CAD converter 3D_Evolution and is now introducing native interfaces for reading Solidedge and writing Nx and Solidworks files. It supports a wide range of formats such as Catia, Nx, Creo, Solidworks, Solidedge, Inventor, Step, and Jt, facilitating smooth interoperability between different systems and collaboration for engineers and designers in development environments with different CAD systems.

CT CoreTech-nologie has further developed its state-of-the-art CAD converter 3D_Evolution and is now introducing native interfaces for reading Solidedge and writing Nx and Solidworks files. It supports a wide range of formats such as Catia, Nx, Creo, Solidworks, Solidedge, Inventor, Step, and Jt, facilitating smooth interoperability between different systems and collaboration for engineers and designers in development environments with different CAD systems.

Learn more.

Top 5 reasons for solder joint failure

Solder joint reliability is often a pain point in the design of an electronic system. According to Tyler Ferris at ANSYS, a wide variety of factors affect joint reliability, and any one of them can drastically reduce joint lifetime. Properly identifying and mitigating potential causes during the design and manufacturing process can prevent costly and difficult-to-solve problems later in a product lifecycle.

Solder joint reliability is often a pain point in the design of an electronic system. According to Tyler Ferris at ANSYS, a wide variety of factors affect joint reliability, and any one of them can drastically reduce joint lifetime. Properly identifying and mitigating potential causes during the design and manufacturing process can prevent costly and difficult-to-solve problems later in a product lifecycle.

Read this informative ANSYS blog.

Advanced overtemp detection for EV battery packs

Littelfuse has introduced TTape, a ground-breaking over-temperature detection platform designed to transform the management of Li-ion battery systems. TTape helps vehicle systems monitor and manage premature cell aging effectively while reducing the risks associated with thermal runaway incidents. This solution is ideally suited for a wide range of applications, including automotive EV/HEVs, commercial vehicles, and energy storage systems.

Littelfuse has introduced TTape, a ground-breaking over-temperature detection platform designed to transform the management of Li-ion battery systems. TTape helps vehicle systems monitor and manage premature cell aging effectively while reducing the risks associated with thermal runaway incidents. This solution is ideally suited for a wide range of applications, including automotive EV/HEVs, commercial vehicles, and energy storage systems.

Learn more.

Benchtop ionizer for hands-free static elimination

EXAIR's Varistat Benchtop Ionizer is the latest solution for neutralizing static on charged surfaces in industrial settings. Using ionizing technology, the Varistat provides a hands-free solution that requires no compressed air. Easily mounted on benchtops or machines, it is manually adjustable and perfect for processes needing comprehensive coverage such as part assembly, web cleaning, printing, and more.

EXAIR's Varistat Benchtop Ionizer is the latest solution for neutralizing static on charged surfaces in industrial settings. Using ionizing technology, the Varistat provides a hands-free solution that requires no compressed air. Easily mounted on benchtops or machines, it is manually adjustable and perfect for processes needing comprehensive coverage such as part assembly, web cleaning, printing, and more.

Learn more.

LED light bars from AutomationDirect

Automation-Direct adds CCEA TRACK-ALPHA-PRO series LED light bars to expand their offering of industrial LED fixtures. Their rugged industrial-grade anodized aluminum construction makes TRACKALPHA-PRO ideal for use with medium to large-size industrial machine tools and for use in wet environments. These 120 VAC-rated, high-power LED lights provide intense, uniform lighting, with up to a 4,600-lumen output (100 lumens per watt). They come with a standard bracket mount that allows for angle adjustments. Optional TACLIP mounts (sold separately) provide for extra sturdy, vibration-resistant installations.

Automation-Direct adds CCEA TRACK-ALPHA-PRO series LED light bars to expand their offering of industrial LED fixtures. Their rugged industrial-grade anodized aluminum construction makes TRACKALPHA-PRO ideal for use with medium to large-size industrial machine tools and for use in wet environments. These 120 VAC-rated, high-power LED lights provide intense, uniform lighting, with up to a 4,600-lumen output (100 lumens per watt). They come with a standard bracket mount that allows for angle adjustments. Optional TACLIP mounts (sold separately) provide for extra sturdy, vibration-resistant installations.

Learn more.

World's first metalens fisheye camera

2Pi Optics has begun commercial-ization of the first fisheye camera based on the company's proprietary metalens technology -- a breakthrough for electronics design engineers and product managers striving to miniaturize the tiny digital cameras used in advanced driver-assistance systems (ADAS), AR/VR, UAVs, robotics, and other industrial applications. This camera can operate at different wavelengths -- from visible, to near IR, to longer IR -- and is claimed to "outperform conventional refractive, wide-FOV optics in all areas: size, weight, performance, and cost."

2Pi Optics has begun commercial-ization of the first fisheye camera based on the company's proprietary metalens technology -- a breakthrough for electronics design engineers and product managers striving to miniaturize the tiny digital cameras used in advanced driver-assistance systems (ADAS), AR/VR, UAVs, robotics, and other industrial applications. This camera can operate at different wavelengths -- from visible, to near IR, to longer IR -- and is claimed to "outperform conventional refractive, wide-FOV optics in all areas: size, weight, performance, and cost."

Learn more.

Orbex offers two fiber optic rotary joint solutions

Orbex Group announces its 700 Series of fiber optic rotary joint (FORJ) assemblies, supporting either single or multi-mode operation ideal for high-speed digital transmission over long distances. Wavelengths available are 1,310 or 1,550 nm. Applications include marine cable reels, wind turbines, robotics, and high-def video transmission. Both options feature an outer diameter of 7 mm for installation in tight spaces. Construction includes a stainless steel housing.

Orbex Group announces its 700 Series of fiber optic rotary joint (FORJ) assemblies, supporting either single or multi-mode operation ideal for high-speed digital transmission over long distances. Wavelengths available are 1,310 or 1,550 nm. Applications include marine cable reels, wind turbines, robotics, and high-def video transmission. Both options feature an outer diameter of 7 mm for installation in tight spaces. Construction includes a stainless steel housing.

Learn more.

Mini tunnel magneto-resistance effect sensors

Littelfuse has released its highly anticipated 54100 and 54140 mini Tunnel Magneto-Resistance (TMR) effect sensors, offering unmatched sensitivity and power efficiency. The key differentiator is their remarkable sensitivity and 100x improvement in power efficiency compared to Hall Effect sensors. They are well suited for applications in position and limit sensing, RPM measurement, brushless DC motor commutation, and more in various markets including appliances, home and building automation, and the industrial sectors.

Littelfuse has released its highly anticipated 54100 and 54140 mini Tunnel Magneto-Resistance (TMR) effect sensors, offering unmatched sensitivity and power efficiency. The key differentiator is their remarkable sensitivity and 100x improvement in power efficiency compared to Hall Effect sensors. They are well suited for applications in position and limit sensing, RPM measurement, brushless DC motor commutation, and more in various markets including appliances, home and building automation, and the industrial sectors.

Learn more.

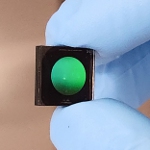

Engineered ‘sand' may help cool electronic devices

By John Toon, Georgia Tech

Baratunde Cola would like to put sand into your computer. Not beach sand, but silicon dioxide nanoparticles coated with a high dielectric constant polymer to inexpensively provide improved cooling for increasingly power-hungry electronic devices.

The silicon dioxide doesn't do the cooling itself. Instead, the unique surface properties of the coated nanoscale material conduct the heat at potentially higher efficiency than existing heat sink materials. The theoretical physics behind the phenomenon is complicated, involving nanoscale electromagnetic effects created on the surface of the tiny silicon dioxide particles acting together.

A thermal probe tests heat conductance in a sample of silicon dioxide nanoparticles. The material could potentially conduct heat at an efficiency higher than that of conventional materials. [Credit: Rob Felt, Georgia Tech]

The bottom line could be a potentially new class of high thermal conductivity materials useful for heat dissipation from power electronics, LEDs and other applications with high heat fluxes.

"We have shown for the first time that you can take a packed nanoparticle bed that would typically act as an insulator, and by causing light to couple strongly into the material by engineering a high dielectric constant medium like water or ethylene glycol at the surfaces, you can turn the nanoparticle bed into a conductor," said Cola, an associate professor in the George W. Woodruff School of Mechanical Engineering at the Georgia Institute of Technology. "Using the collective surface electromagnetic effect of the nanoparticles, the thermal conductivity can increase 20-fold, allowing it to dissipate heat."

The research, which involved both theory and experiment, has been published online in the journal Materials Horizons, and was highlighted in the July 8 issue of the journal Science. The work was supported by the Air Force Research Laboratory and the U.S. Air Force. Co-authors include Professor James Hammonds at Howard University, and graduate students Eric Tervo from Georgia Tech and Olalekan Adewuyi from Howard University.

In the last several years, theoretical papers have predicted the ability of surface phonon polaritons to increase thermal conduction in nanomaterials made from polar materials like silicon dioxide. Polaritons are quantum quasiparticles produced by strong coupling of electromagnetic waves with an electric or magnetic dipole-carrying excitation. In the specific case of surface phonon polaritons, the electromagnetic waves are coupled to a certain frequency and polarization of vibrating atoms in the material known as optical phonons. When materials are reduced to sizes below 100 nanometers, the surface properties of the material dominate over bulk properties, allowing phonons of heat to flow from particle to particle in the closely packed bed with the assistance of the coupled electromagnetic waves.

Although researchers could not previously measure heat flow from surface phonon polaritons due to experimental difficulties, they have observed their wave propagation when light hits the surface of a nanostructure material, suggesting a potential role in heat dissipation. In addition to the first measurement of heat flow, Cola and his collaborators also found that the effect can occur when thermal energy is added to a packed bed of nanoparticles.

"What we are also showing for the first time is that when you have nanoparticles of the right type in a packed bed, that you don't have to shine light on them," he explained. "You can just heat up the nanoparticles and the thermal self-emission activates the effect. You create an electrical field around the nanoparticles from this thermal radiation."

The researchers decided to experiment with those special properties, first using water to coat the nanoparticles and turn the silicon dioxide nanoparticle bed into a conductor. But the water coating was not robust, so the researchers switched to ethylene glycol, a fluid commonly used in vehicle antifreeze. The new combination increased the heat transfer by a factor of 20 to approximately 1 watt per meter-kelvin, which is higher than the value ethylene glycol or silicon dioxide nanoparticles could produce alone, and competitive with expensive polymer composites used for heat dissipation.

"You could basically take an electronic device, pack these ethylene glycol-coated nanoparticles in the air space, and it would be useful as a heat dissipation material that at the same time, won't conduct electricity," said Cola. "The material has the potential to be very inexpensive and easy to work with."

Silicon dioxide was chosen because its crystalline lattice can generate resonant optical phonons -- necessary for the effect -- at approximately room temperature. Other materials could also be used, but the silicon dioxide nanoparticles provide a good compromise of properties and cost.

"The resonance frequency, converted into the thermal radiation temperature for silicon dioxide, is around 50 degrees Celsius," said Cola. "With this material, we can turn on this effect at a temperature range that a microelectronic device is likely to see."

Though the ethylene glycol works well, it will eventually evaporate. For that reason, Cola plans to identify polymeric materials that could be adsorbed to the silicon dioxide nanoparticles to provide a more stable coating with a reasonable product lifetime.

The effect depends on the collective action of the silicon dioxide nanoparticles.

"We are basically showing a macroscopic translation of a nanoscale effect," Cola said. "Even though the nanoparticle bed is a bulk assembly, it is a bulk assembly that has a lot of internal surface area. The internal surface area is the gateway by which it interacts with the electromagnetic field -- the light and the heat."

So far, the effect has been demonstrated in small amounts of silicon dioxide nanoparticles. Another step would be to scale up the study to demonstrate that heat can be transferred longer distances in larger volumes of the material, Cola said.

"The rate at which the thermal energy goes from one side of the particle to the other side of the particle is constant throughout the nanoparticle bed, so it shouldn't matter how thick the nanoparticle bed is," he explained. "When these particles are close enough together, their modes are coupled, which allows the energy to transport."

Further testing would be needed to ensure the long-term efficiency and to confirm that there are no impacts on the reliability of the electronic devices cooled with the technique, Cola said.

Published August 2016

Rate this article

View our terms of use and privacy policy